Writing and enforcing standard operating procedures (SOPs) for medical devices is required by FDA, ISO and other regulatory bodies. How effective are your SOPs?

However, many medical device companies find this process to be rather confusing, resulting in ineffective procedures being written and followed. This confusion will likely be the root cause for subsequent inspectional observations that result in more serious consequences for the manufacturer, such as 483s and warning letters.

When we look at 483s and warning letters, issues such as CAPAs remain a prominent problem, but what lies at the root cause of the CAPA issue? If we dig deeper, we’ll often find that the company doesn’t have effective, written SOPs for CAPA, or for other required procedures.

If done well, your SOPs form clear guidelines for your team to follow. On the other hand, if not done well or not enforced, things can easily go awry. Let’s look at all aspects of SOPs for medical devices, including when they are needed and how to write them effectively:

BONUS CONTENT: Download your free copy of our Tips for Building Consistent QMS Procedures.

What is an SOP?

An SOP (Standard Operating Procedure) is a set of mid-to-high level written instructions that documents how an organization or department should achieve specific tasks. SOPs may be developed for procedures that are routine and regular, such as document control, and should also be developed for important tasks that aren’t so regular, like CAPAs.

As a medical device company, your SOPs form an integral part of an effective quality management system. They serve as guidelines to the teams who are carrying out certain tasks, to ensure those are executed properly and in a consistent manner. They address process and safety requirements to ensure the highest quality and effectiveness possible for that product.

Having properly documented SOPs is imperative for medical device companies, especially for preventing any future situations that could warrant an inspectional observation. In the case an issue has already been uncovered, developing and enforcing clear SOPs will serve as an instrumental part of the corrective action of that issue.

When are SOPs required for medical devices?

Medical device companies must adhere to a lot of requirements to maintain regulatory compliance, and those must be clearly documented. To name just a few, separate SOPs are required for each of the following:

- Document controls

- Manufacturing

- Transporting and storing products

- Supplier management

- Reporting problems or failures

- Initiating and conducting CAPA

- Risk management

- Design controls

- Training

- Clinical evaluation

The list goes on.

Essentially, every procedure you can think of, which is part of the routine operations of your company should have an SOP.

All SOPs should do the following:

- Document how activities are to be performed to maintain consistency and to support quality practices.

- Describe the analytical processes validation and qualification processes, and processes for maintaining, calibrating, and using the equipment.

- Maintain quality control and assurance processes, ensuring compliance with regulations.

What makes SOPs effective?

A well-written SOP offers clear, unambiguous instruction so that any deviations in the procedure are unlikely. They should describe the overall process that is to be followed. Here are some of my top tips for writing effective SOPs...

Always keep the end-user in mind

It always pays to take a practical approach when writing SOPs. The author might be the expert on the procedure, but they’re not necessarily the end-user who will be following and referencing that SOP. How do you ensure that you have the perspective of the end-user covered?

Let's step out of our medical device shoes for a moment so we can gain an unbiased perspective by using a more universal example: ready-to-assemble furniture. These are supposed to be put together following a standard procedure, right? But have you ever found yourself reading the instructions to find they don’t make sense, or the pieces don’t seem to match what you have in your hands?

Maybe the instructions reference a noncorresponding part, or the wording is just flatout confusing. You might choose to ignore the instructions completely and assemble what you believe most closely resembles the factory image on the front of the box; only to later find the finished product has a permanently wobbly part.

Now take that universal example and apply it to the design and development of your medical device. And now it’s easy to see just how quick and easy it can be for poorly written SOPs to manifest into a potentially dangerous situation for your end-users. As the expert writing the procedure, take a step back and consider:

- Have I written clearly and concisely?

- Your sentences should be brief, use common terms and use good grammar.

- Avoid being overly technical when simpler terms can communicate the same message.

- Have I followed a step-by-step format?

- This is simply the easiest format for people to follow when conducting a procedure.

- Use simple, directive words such as “identify,” “evaluate,” “adjust,” “investigate,” concisely convey what is expected. Using a passive voice can confuse the direction.

- Have I been action-orientated?

- Have I been precise?

- General descriptions like “typical” or “periodically” tend to be ambiguous and lead to people having to interpret the SOP (which they should never have to do).

- For example, consider the difference between these two sentences:

- Internal audits should be conducted periodically

- Internal audits should be conducted annually, prior to November 30.

- Have I formatted the SOP clearly?

- Dense paragraphs are difficult for people to read and information may get lost in them.

- Formatting such as bullets and lists helps to communicate more clearly.

- Have I correctly used the terms “may,” “must” and “should?”

- These translate to “you have a choice,” “this is mandatory” and “this may be conditional,” so it’s important that they are used within the right context.

Follow a clear format

Consistently following a clear format helps to ensure your SOPs are interpreted and followed consistently. Here is a good, basic outline to use when formatting your SOPs:

- Header

- Includes the title, document number and version. It should clearly identify the activity.

- Purpose

- This is one or two sentences that define the intent of the whole document. It needs to be detailed enough to convey this intent, without going into too much detail.

- Scope

- This defines to whom or what the SOP applies. When you write this, check it to ensure it’s not open to interpretation. Sometimes it makes sense to include information on what is out of scope too, just to be clear.

- References and Related Documents

- This is where any related documents and references can be noted or linked to. For example, you might include links to related regulations.

- Definitions

- This is the section to spell out definitions for any terms or acronyms that the end-user may not understand.

- Roles and responsibilities

- Which roles are responsible for executing the activities in the procedure?

- Procedure

- The “meat” of the procedure, broken down into major steps, with any individual action steps and notes included for each major step. Procedures should meet compliance needs without containing so much material that they constitute a compliance risk themselves.

- Appendices

- For example, flow-charts to use as visual explainers for procedures.

- Revision history

- This records what changes were made, when and why.

- Approval signatures

- Usually found either at the very beginning, or the very end.

Avoid these common mistakes when writing SOPs

There are a few common mistakes that companies make when writing SOPs - here are some to avoid:

- Copying regulatory guidelines word-for-word - This results in a regurgitation of the regulation rather than providing end-users with clear instructions specific to your product.

- Too many roles and responsibilities listed under a single SOP. This can get confusing - a better solution is to break that SOP down into two or three clearly defined SOPs.

- Not keeping track of revision history or version control. This is a requirement, but it can get tricky to keep up, especially if your company uses a paper-based system.

- Not getting SOPs reviewed by end-users first. How do you know you’ve written clearly enough so that the end-user understands the SOP? Get SOPs reviewed by key parties before they are put into practice.

Take the hassle out of building and maintaining SOPs

All of your SOPs should be documented clearly, following a standard format. Importantly, once your SOPs have been established, you need to be regularly checking to make sure they’re being adequately followed. FDA sends warning letters to companies for not having adequate SOPs, as well as not following them.

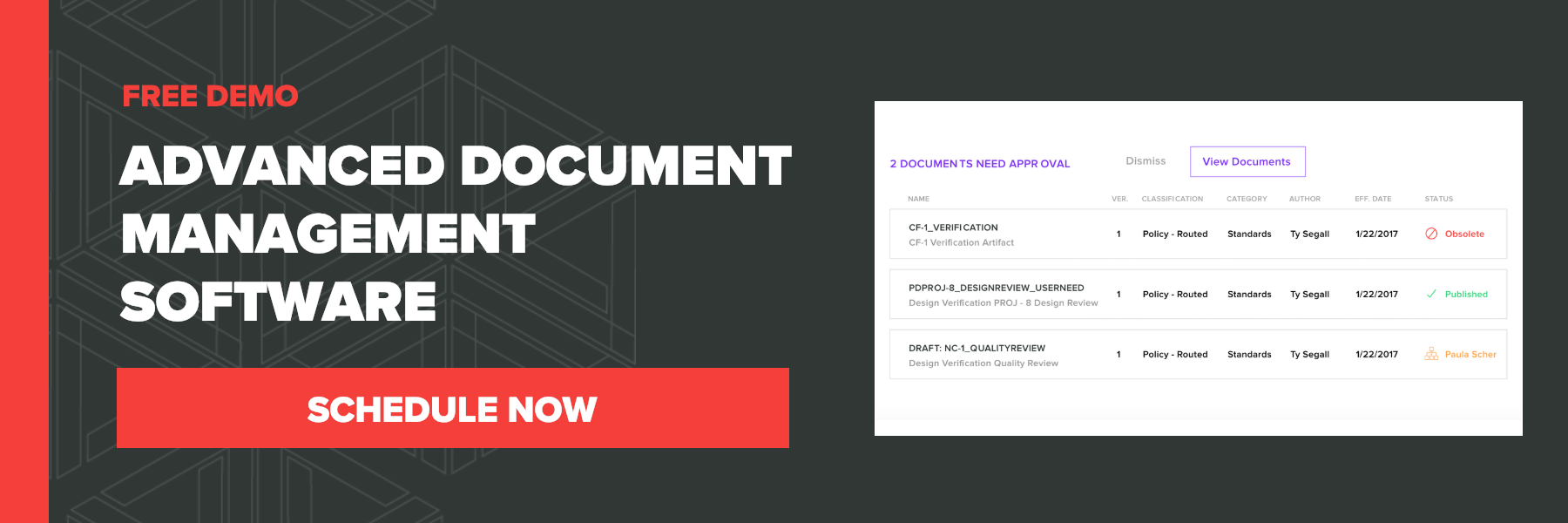

Creating and maintaining SOPs does not need to be a cumbersome task. Greenlight Guru takes the hassle out of building and maintaining SOPs by simplifying the entire process with built-in SOP templates and workflows.

Companies can manage every new and existing procedure throughout the purpose-built eQMS software, which provides teams with full traceability and visibility across the cloud-based platform, and managers with quick and secure approval of documents with the click of a button.

Jon Speer is a medical device expert with over 20 years of industry experience. Jon knows the best medical device companies in the world use quality as an accelerator. That's why he created Greenlight Guru to help companies move beyond compliance to True Quality.

Related Posts

6 Most Common Mistakes When Implementing ISO 13485

How to Master the CAPA Process: Complete Guide with Visual

4 Tips for Handling Nonconformances

Get your free PDF

Tips to Building Consistent QMS Procedures