Creating a Supplier Scorecard for Medical Device Supplier Management

A supplier scorecard is one of the most effective tools medical device manufacturers have for assessing the performance of their suppliers.

Supplier scorecards help you track and review key metrics for each of your suppliers, which in turn makes it easier to spot trends and stay on top of any issues. A scorecard isn’t the only tool in your supplier management toolbox, but it is one of the most effective.

So let’s take a look at how a supplier scorecard works, what data you should track, and how you should use that data to determine the health of your relationship with a supplier.

What is a supplier scorecard?

Once you’ve qualified a supplier and moved them onto your approved supplier list (ASL), the job of managing that supplier can finally begin. That job includes monitoring their performance on an ongoing basis—and a supplier scorecard is a great way to do that.

In the most basic sense, a scorecard is just a set of metrics you want to track and a system for weighting those metrics based on their importance to you. Every month (or at least every quarter), you’ll sit down to review the metrics and assess the health of your supplier relationships.

Click here to download your free PDF of the eBook, Ultimate Guide to Supplier Management for Medical Device Companies.

The biggest benefit of using supplier scorecards is that they increase objectivity in your supplier monitoring. Regularly collecting the same data makes it easier to see if an issue with a supplier is a one-off event or part of a larger trend.

It can also simplify decision-making. If you establish a certain minimum score for suppliers ahead of time, then you have an objective reason for auditing a supplier if there is a dip in performance. And if they continue to fail to meet that minimum score, you’ll also have reason to begin searching for a new supplier altogether.

What type of data do you collect for your supplier scorecard?

The metrics you choose for your supplier scorecard will in large part depend on the type of supplier and what they’re supplying you with.

For a product supplier that’s providing a particular item, like a part for your device, you might track metrics such as:

-

First time in full. How often do you get the shipment in your contract on time? And how often does the entire amount come in at once? Are there orders that are delayed or separated into multiple shipments because of delays on the supplier's end?

-

Nonconforming product. Does the product you’ve received comply with the specifications in your formal quality agreement?

-

Undamaged material. What is the state of the product when it gets to you? What is the pass/fail rate for their product?

-

SCARs raised. Have you had to raise Supplier Corrective Action Requests (SCARs) with this supplier? How quickly were these issues resolved? You’ll want to track how often it happens, but you should also track what the SCARs are for. Are you raising SCARs for the same issue over and over?

For a service supplier, you may track some of the same metrics, such as SCARs raised, but there will be other data to record as well. Things like:

-

Lead times and responsiveness. How long does it take them to begin providing you with their service or fixing a problem when you report an issue? How responsive are they when you contact them?

-

Quality of service. This is more subjective, but you can also evaluate a service provider based on whether they execute the service according to the terms you’ve agreed upon. For example, if you bring on a contractor for a specific project, have they delivered exactly what was in the agreement, or were there changes or deviations in the service?

What you track is up to you. Just don’t miss the forest for the trees—gathering too much data on inconsequential supplier metrics can distort your scorecard.

How should you use your supplier scorecard to make decisions about a given supplier?

Once you’ve decided which performance categories you’ll track, the next step is to develop a weighted scoring approach. The goal here is to ensure that serious issues have more “weight” in your scoring than minor issues.

A handful of non-conformances that are within your acceptable quality limit probably won’t be weighted as heavily as a handful of delayed shipments that shut down production for weeks at a time.

At the end of every month (or at least every quarter) you’ll sit down and review the scorecards to evaluate how each of your suppliers is performing.

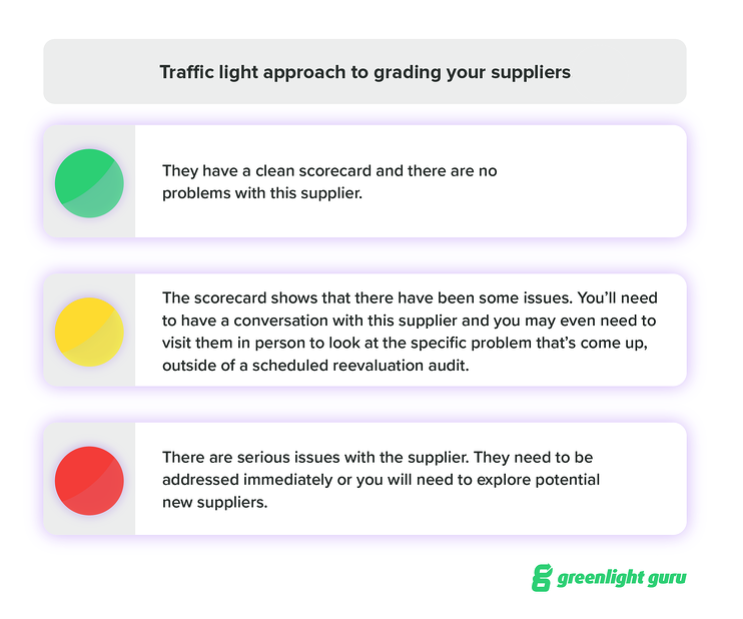

There are different methods for doing this, but a “traffic light” framework is a popular method.

-

Green: The scorecard is clean and there are no problems with this supplier

-

Yellow: The scorecard shows there have been some issues. You’ll need to have a conversation with this supplier and you may even need to visit them in person to look at the specific problem that’s come up, outside of a scheduled reevaluation audit.

-

Red: There are serious issues with the supplier. They need to be addressed immediately or you will need to explore potential new suppliers.

With a good scoring framework in place, you’ll be able to quickly and easily understand how each of your suppliers is doing—and when you need to take action.

Get better aligned with your suppliers using Greenlight Guru

Ultimately, your goal should be to achieve a long-lasting and mutually beneficial relationship with all your suppliers. And one way to make that relationship easier for everyone is to have a single, secure way to share key documents and tasks with external stakeholders.

With Greenlight Guru’s Quality Management Software, you’ll have a single source of truth that helps you assure alignment with suppliers by leveraging the ability to share critical documents such as SOP’s, work instructions, or product-specific details. Your team can also proactively monitor supplier performance, track supplier actions, and conduct supplier audits all within a fully traceable system.

So if you’re ready to optimize your supplier management efforts, get your free demo of Greenlight Guru today!

Benjamin Bancroft is a Medical Device Guru at Greenlight Guru who enjoys working on audits, CAPAs and Root Cause Analysis. He is a Quality and Regulatory Manager who began his career maintaining the QMS for multiple companies as a CAPA and audit SME. He enjoys helping customers successfully navigate regulations to...

Related Posts

Approved Supplier List: How To Add Suppliers to Your ASL in 7 Steps

The Difference Between Managing Product & Services Suppliers in MedTech

Ultimate Guide to Supplier Management for Medical Device Companies

Get your free eBook PDF

Ultimate Guide to Supplier Management for Medical Device Companies